Ever since the early days of SPAR 3D coming to Diversified Communications (you may remember it as Spar Point Group back then), there's been lots of talk of introducing the shipbuilding community to the 3D data capture community. See, Diversified also owns the terrific Workboat Magazine, which spends a lot of time covering the manufacture and refurbishment of various vessels, from tugboats to ferries to offshore service vessels. Surely, we figured, there would be interest in a technology that could quickly recognize deviations from plan or analyze damage based on before and after scans.

But that big crossover hasn't yet really materialized, even though these vessels are essentially floating buildings with every need for mapping physical space that buildings have.

That's why I've been closely following all of the publicly released information about the restoration of the TS Queen Mary. No, not the HAUNTED Queen Mary, out in California, the TS Queen Mary, a steamship built in 1933 in Scotland and then left to rot in London before the Friends of the Queen Mary undertook a mission to save and restore the old girl:

TS Queen Mary closed for business in January 2009 when Westminster Council would not renew the lease for her berth, preferring instead to develop the area for water bus services. The ship was sold to a French consortium that had plans to convert her for use as a floating hotel, in La Rochelle. The ship was towed from London to Tilbury, in November 2009. The plans fell through and the ship was sold again in September 2011 to a private buyer, Ranjan Chowdhury.

TS Queen Mary was arrested by the Port of Tilbury, in July 2015, due to non-payment of berthing dues. Friends of TS Queen Mary tendered a bid for the ship, and was announced as the preferred bidder in August 2015. On 18th August 2015, TS Queen Mary was visited by representatives from Ferguson Marine, V Ships and the MCA, and was extensively examined. The ship was found to be in remarkably good condition, and Friends of TS Queen Mary were then able to complete a bill of sale, taking the ship into the hands of a dedicated Charity for the first time in her life.

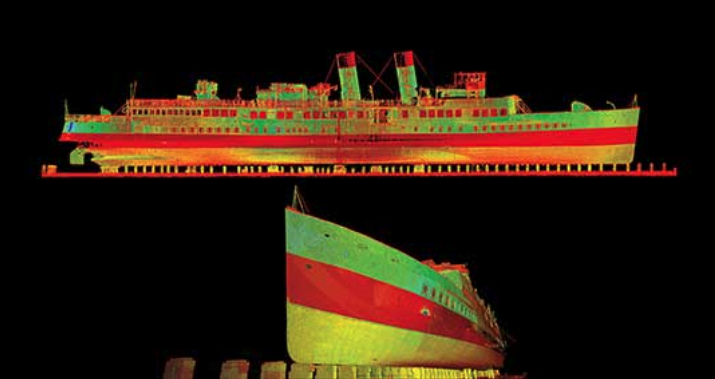

My interest was piqued back in 2019 by news that the marine consultants, Brookes Bell, had decided to commission a full laser scan of the interior and exterior to create a 3D model of the ship's structure after just about everything -- seats, fittings, etc. -- had been ripped out in order to begin the rehabilitation.

For the work, they turned to Al Rawlinson, head of data acquisition at School of Simulation and Visualisation at the Glasgow School of Art, who you may remember as the guy who put together "The Art of the Point Cloud" (as an aside, Al also used his 3D expertise to help create PPE for Scottish health care workers back in April. Well done, Al!). The team used a Z+F Imager 5010C for the gig.

“Given the limited access I had to the ship in terms of time," Rawlinson told Photonics.com, "I needed to use a scanner which was highly portable, very quick to use, and which could capture large amounts of high quality data very quickly."

There's a pretty killer fly through of the resultant point cloud data here, which I unfortunately can't show you immediately because Wordpress doesn't have a great way to embed Facebook videos (which is pretty amazing, considering the ubiquity of both platforms, but I'm guessing there's a competitive thing there).

And all of that looks and sounds great, but, at the time, Brookes Bell was mostly interested in using the 3D data to "monitor rates of decay and damage over the years." Admirable, but not all that exciting. Wouldn't it be much better if they could use the data to actually inform the new design needed to refurbish the ship?

Enter AVEVA. Late this summer, the company donated $100k+ worth of software to help Brookes Bell manage the point cloud data and incorporate it into 3D design. The previous software package wasn't allowing for integration of the point cloud data and was introducing errors when they tried to manually model from it. And this may finally be the crossover into shipbuilding we've been waiting for:

AVEVA’s advanced software has allowed the team at Brookes Bell to 3D model TS Queen Mary’s structure accurately and in detail. The model also cleverly links to construction and production drawings, so that shipyard production information for the vessel’s upcoming steel renewals can be produced more efficiently than by any other means.

Once the detailed design phase is completed, AVEVA will utilise the data harvested from TS Queen Mary – in partnership with Friends of TS Queen Mary – for internal training and future product testing. It is fitting that TS Queen Mary will play a role in supporting the development of vessels for decades to come.

“This is a very exciting project," said Andy McGibbon, Senior Naval Architect, Brookes Bell. "We’re able to completely transform the design and restoration process – driving huge improvements in design efficiency, quality, ensuring that the design is fault free and that the vessel is sympathetically restored for the benefit of future generations.”

That's a pretty ringing endorsement of laser scanning and 3D design software for the maritime industry. And that maritime industry is a big one. A general estimate puts the shipbuilding and repair market at something like $30 billion annually here in the United States. How does laser scanning start to get a bigger piece of that pie? Through more documented successful workflows like this one.

Watch out for the TS Queen Mary. When she launches in her new shiny look, there will be a completed laser scanning case study just waiting to happen.