When we hear about a new breakthrough, our instinct is to let our imaginations run wild. But, as anyone who has followed the maturation of a technology along Gartner’s hype cycle will tell you, it’s often the more prosaic uses of a technology that will determine its true value in the long term.

Today, the MIT Technology Review’s newsletter featured a short article about a warehouse robot developed by Ocado, A UK grocery retailer that operates exclusively online.

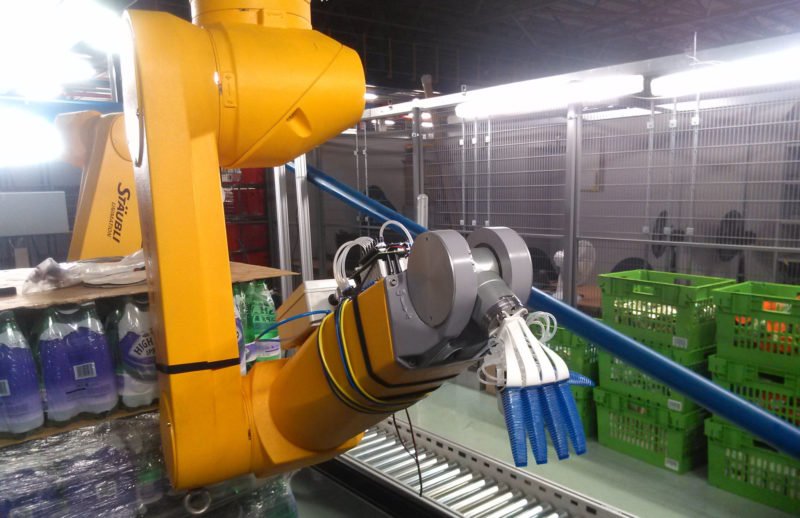

As the article describes it, the engineers didn’t bother to build 3D models of the products themselves because they knew the robot would be directed at large crates holding a large number of identical items. Instead, they designed the robot to use other means to find the crates, and then use 3D cameras to find a single item in that box that would be easiest for it to grab onto with a suction cup.

“It looks for patches in the scene that are flat enough, horizontal enough, and big enough to pick up,” said Graham Deacon, leader of the robotics research team at Ocado.

Once the arm has scanned the item to register that it has been taken, it uses its 3D cameras again to place the item in a customer’s order, like a supermarket bag boy placing your lettuce on top of a pile of cans instead of piling them all together.

It’s not in use yet, as Tech Review notes that it will be tested in a warehouse next year.

Though this particular use of 3D technologies may not be as interesting as, say, scanning a building, the automation of warehouse work could have an outsized effect on our daily lives. As with drones, a significant portion of the value of 3D technology may come from automating dirty, dull, and dangerous tasks.