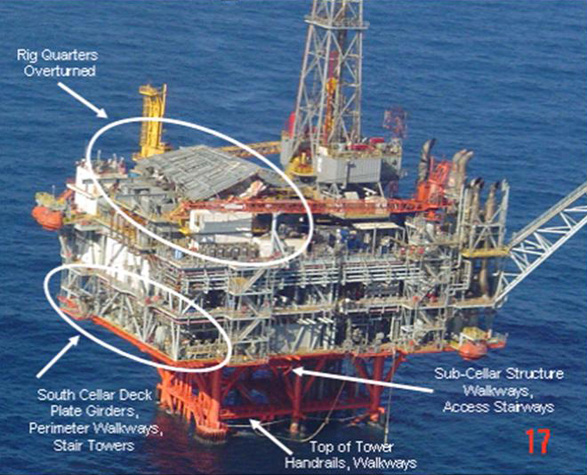

On September 14-16, 2004 Hurricane Ivan swept through the Gulf of Mexico. The hurricane’s eye passed almost directly over Chevron Corporation-operated Petronius Platform in Viosca Knoll Block 786 approximately 130 miles southeast of New Orleans, damaging rig crew quarters, deck structures and production equipment. Petronius, which averaged 42 thousand barrels of crude oil and 65 million cubic feet of gas per day before the hurricane – approximately 3.7% of the total daily production from the Gulf of Mexico – was totally shut-in. 3D laser scanning was used to assess the damaged structures and equipment on the platform – the technique shortened the expected repair schedule by 24 days compared with traditional methods and helped remove the structural steel repair from the critical path. Petronius returned to 75% pre-Hurricane Ivan production rates on March 15 after being shut-in for 175 days. Production has subsequently been ramped up to 100% of pre-hurricane levels. Petronius is 50% owned by Chevron and 50% by Marathon Oil Corporation.

Under the direction of Chevron’s project manager Bob Squires, a damage assessment plan was developed which included providing safe access to Petronius. On October 7 a structural engineering team lead by Chevron’s Jose Abadin and assisted by Barry Reed of W.H. Linder & Associates Inc. performed a visual inspection of the damage to identify possible repair solutions. The inspection revealed that measurements of the damaged structural members would be needed to quantify an acceptable solution. Reed and Abadin concluded that 3D laser scanning would be the right application to survey the damaged structure and equipment on Petronius. A scope of work was developed for the laser scanning project by W.H. Linder and laser scanning service provider READCO and was coordinated with Abadin and the Chevron operations personnel for execution.

3D laser scanning work process for capturing as-is conditions

On October 16 a damage assessment team led by READCO principal Troy Di Natali mobilized to Petronius to capture the post-Hurricane Ivan existing conditions. The team performed 30 scans of the structure in 6 days using a Leica HDS3000 laser scanning system, collecting 3 gigabytes of point cloud data. A 3D AutoCAD solid model developed from this point cloud data was delivered to Linder and Chevron 21 days following the completion of the scanning. The assessment data was required to perform structural and stress analysis of the damaged structural members, piping and equipment.

The first phase of the structural analysis of the platform required analyzing the load-carrying capacity of deformed plate girders on the cellar deck 60 feet above sea level. The ferocity of Ivan is apparent – the bottom of the cellar deck plate girders are located 5 feet above the 100-year wave crest elevation. According to David Watts, lead design engineer for Linder’s onshore design team, laser scanning of the beams and subsequent importing of the captured geometry into AutoCAD indicated plastic deformation of the girders of up to 30 degrees (see Figure 2 above). The beam geometry was imported into SACS, a structural analysis application, to determine the load-carrying capacity of the deformed structure frames. Linder structural design engineers Gwen Accardo and Ekrem Celebi modeled the steel required for repairs using SACS and PDMS.

Matt Dorrington, Chevron’s lead facility engineer, had the damage assessment team measure the deformation of the export gas pipeline from the +60 feet elevation to the +12 feet elevation. The measured pipeline geometry was modeled in 3D AutoCAD and compared with the original PDMS design model. Displacement data was exported to CAESAR for stress analysis (Figure 2). A topographic assessment was also performed to determine the deflection of the walking surfaces of the cellar deck and its potential impact on rotating equipment alignment. Non-destructive testing on the most deformed elements validated the analysis.

Figure 5 is a photograph of the damaged living quarters for the Ensco drilling rig; Figure 6 is a laser scan image of the same area. Note that each pixel in Figure 6 and all other deck scans contains x,y,z information referenced to the platform and original PDMS design coordinate system. According to Watts, the scan data of the living-quarters module was used in planning the demolition and removal of this module.

Lessons learned from Hurricane Lili

Squires applied some of the lessons learned from repairing the damage from Hurricane Lili in October 2002 to planning the repair of Petronius including complete identification of the scope of work and deployment of new technologies and work processes. According to Squires, “The use of laser scanning got Petronius back on line more quickly without compromising safety” by removing the repair of the structural steel from the critical path. Laser scanning allowed the engineering team to get to the decision to replace fewer structural elements sooner because of both the completeness and speed with which the analysis of the load-bearing capabilities of structures could be performed.

Laser scanning shortened the repair schedule by as much as 26 days

Watts and Di Natali estimate the use of laser scanning shortened the repair schedule by as much as 26 days compared with using traditional tape measure/plumb bob-based dimensional data gathering techniques. Schedule reduction was achieved in part because scaffolding did not have to be erected to capture the as-is data. CAN Group rope access specialists were used to position reflectors for control for the damage assessment.

The Chevron project team also notes that the accuracy of the dimensional results ultimately led to less offshore fit-up of fabricated components. According to Di Natali, manual dimensional data gathering methods are also plagued by incomplete data capture, which invariably means sending return crews offshore to capture additional or incomplete information.

Schedule reduction on the project was also achieved through the use of inline generator cleaning services provided by HSI Electric, Honolulu, Hawaii, which removed generator repair from the critical path.

Laser scanning enhances safety of data collection

Incident-free operation for the work was Chevron’s highest priority, according to Squires. Remote data capture techniques such as 3D laser scanning also mean significant safety benefits compared with manual measurement techniques. According to Abadin, laser scanning is a high value for damage assessment of areas that are potentially hazardous because of stored mechanical energy. Using laser scanning, these areas can be assessed without direct physical access.

About Chevron

Chevron Corporation is one of the world’s leading energy companies. With more than 47,000 employees, Chevron conducts business in approximately 180 countries around the world, producing and transporting crude oil and natural gas, and refining, marketing and distributing fuels and other energy products. Chevron is based in San Ramon, CA. More information on Chevron is available at www.chevron.com.

About W.H. Linder

W. H. Linder & Associates, Inc. (LINDER) is a full-service multi-discipline consulting engineering firm serving the oil & gas, refining & petrochemicals, and ports & terminals industries along the US Gulf Coast and in West Africa. The engineering staff represents the disciplines of process, mechanical, civil/structural, electrical/instrumentation, and control systems engineering and programming. LINDER employs approximately 200 professional staff in its New Orleans, LA and Houston, TX offices serving both major operators and independents. LINDER provided the original detailed engineering and design work for the Petronius platform’s topsides. For additional information see www.whlinder.com.

About READCO

READCO (Remote Engineering and Design Company, Inc.) was formed in 2000 by Troy J. Di Natali. The firm specializes in reverse engineering and as-built drawing production, utilizing 3D LIDAR scanning technologies to support all engineering and design disciplines utilized at industrial facilities.

READCO has extensive experience in C.I.S. and Caribbean design projects, providing civil, structural, mechanical, piping/pipeline, instrumentation & control, SCADA, electrical, process systems and chemical engineering services in support of heavy industries including oil & gas production, chemical manufacturing, mining, potable water production and wastewater treatment. More information is available at www.readcoinc.com.