Tenant improvement projects - where construction firms work to refit, renovate or upgrade leased spaces - can present a unique set of challenges. Firms need to work within existing spaces that may or may not have been updated by previous tenants and often require aggressive timelines to get the spaces back on the market. Understanding the existing structure - and capturing it as accurately as possible - lays the foundation for project success. Capturing existing conditions and spaces quickly and accurately can also prevent costly delays and help the work of the renovation start more quickly.

To facilitate their tenant improvement projects, Bulley & Andrews, one of Chicago’s oldest general contractors, have been using laser scanning as part of their BIM coordination process. Last spring, when they took on a project to buildout an office space on the West Loop of Chicago, the scale of the project - over 82,912 square feet over two floors - prompted them to look at a different approach to reality capture.

As Senior Project Manager for the general contractor building space, Baltazar Martinez is responsible for all aspects of construction, day-to-day management and clearing project budgets. For Martinez, getting the scanning done quickly was the priority.

“We have done laser scanning the traditional way on other projects, but this floorplan was particularly large - about 40,000 square feet per floor - so we thought that we’d try something different that might speed up the scanning process, and, in turn, the existing condition modeling.”

To evaluate whether a different approach would provide the time saving that Martinez was hoping for, the team decided to use two methods. They would perform both a traditional laser scan with a tripod-based scanner, and a scan using the NavVis VLX, wearable, front-facing mobile mapping system that scans continuously as a jobsite is walked. Rather than moving from point to point to collect individual scans, the NavVis VLX can be used to scan an entire space by foot.

Previously, Bulley & Andrews had utilized mobile mapping only to capture quick walkthroughs, usually just using the resulting capture to communicate to subcontractors or stakeholders. For this project, they planned to use the scans to inform their BIM coordination.

From two days to two hours

After planning a path for scanning the floorplan, reality capture specialist and technology engineer Chris Hall performed the scan of the massive, open floorplan. While this was not Hall’s first time using the NavVis VLX to perform a scan, it was the first where the output would be used for modeling and BIM.

“We had used the NavVis VLX for a couple of other ‘walkthrough’ projects. We weren’t using it mainly for the point cloud - it wasn’t something we needed for those. This is the first big project where we did point clouds and really looped everyone in.”

For a traditional laser scan of a floorplan this size, repeated overlapping scans would be required to ensure that the locations are accurate and that any occluded spaces were captured. However, because the NavVis VLX uses simultaneous localization and mapping (SLAM) algorithms, stopping is not necessary. The SLAM software is able to capture the surroundings and self-references the wearer’s position as they walk through the site. Without the stop-and-go workflow of traditional scanning, the total scanning time can be drastically reduced.

“I finished in about two and half hours from showing up and getting shown around by the building manager to walking out the door. The person performing the traditional laser scan was there over two days, probably about 12 hours of scanning time,” said Hall.

For Martinez, the result of the time saved on the job site made the return on investment very clear.

“We had multiple floors, we had an area to scan that could have taken potentially a week, and we can now cut down that time to a fraction of that. It is definitely something I plan to look into for bigger projects.”

The Accuracy Question

When SLAM technology first debuted, some questioned its accuracy, and others expressed concern that the resolution would not be high enough to be used in scan-to-BIM applications. But after using the NavVis VLX, this is no longer a question for Gray.

When SLAM technology first debuted, some questioned its accuracy, and others expressed concern that the resolution would not be high enough to be used in scan-to-BIM applications. But after using the NavVis VLX, this is no longer a question for Gray.

“It has come a long way. We compared it to the information that we had on the project, and the heights and measurements worked out perfectly. You get a nice color scan by default, and it all looks nice. I’ve never been concerned with the accuracy of it. I think it’s perfectly good.”

“We were a bit nervous to use it for the first time, but now I think we’re going to be using it more and more. We’re super happy with it so far - we’re excited to see it keep evolving.”

Learn more about the NavVis VLX accuracy >

Speed beyond the scanning step

The time difference between the two methods was so drastic that the traditional laser scanning data was discarded in favor of the point cloud captured by NavVis VLX, said Hall.

“The nice thing with the VLX was that the post-processing was all taken care of. So as opposed to the traditional scanner that we’re using, where you have to stitch your scans together, that was one of the biggest problems that was solved for us by NavVis.”

Kyle Gray, VDC manager for the project, noted that the registration step added even more time to the traditional laser scanning process.

“Not even counting the time it took to come back to the office and get it all registered, we had moved beyond to the next steps with the NavVis VLX data before the traditional laser scanning data was ready to go. We were already one or two steps further down the road, so it would have been pointless to go back.”

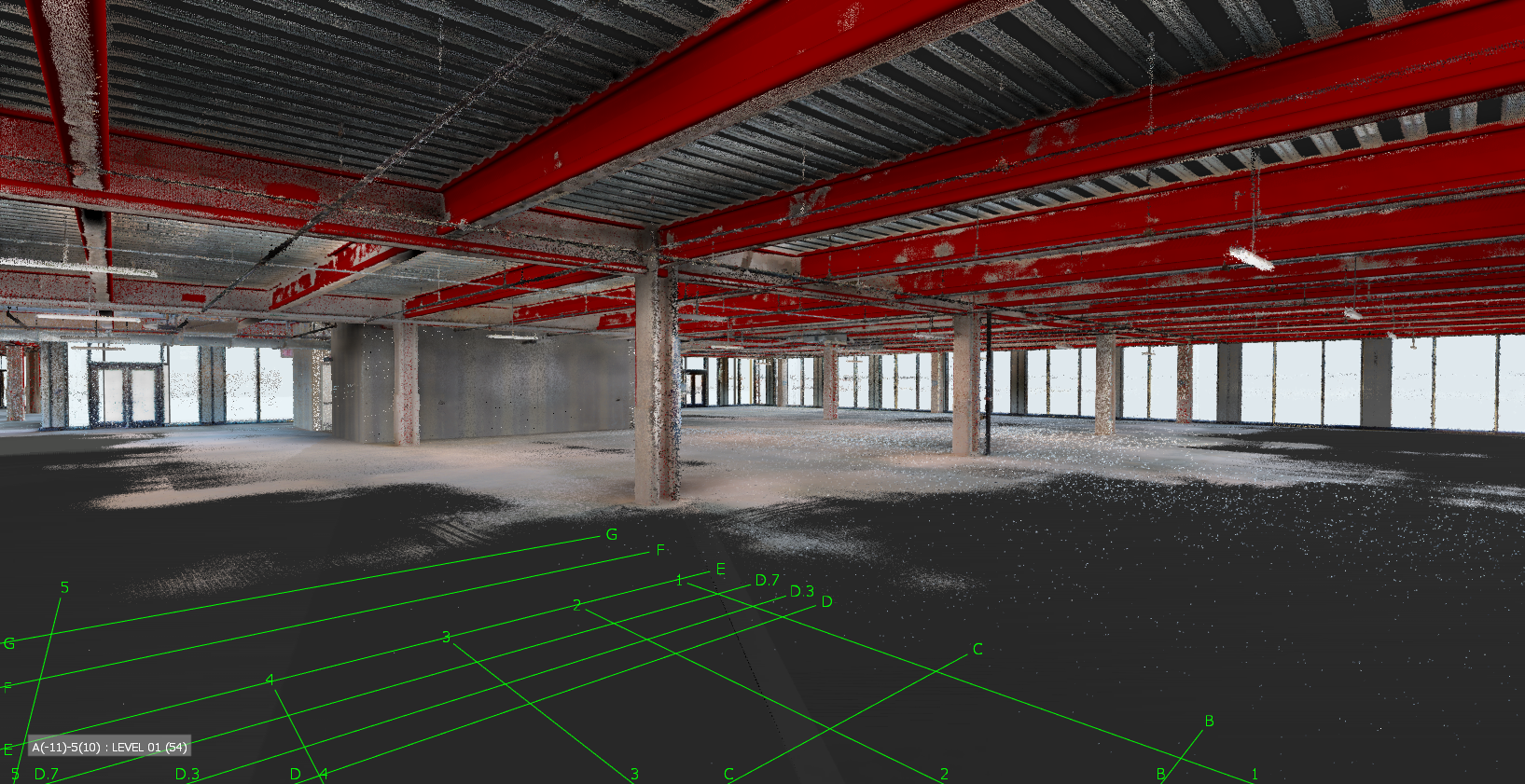

Gray used the colored point clouds captured with NavVis VLX to create a Revit model, and commented that the colored point cloud scans even helped him to quickly discern different pieces of the building when creating the models. Once the model was created, Gray also made sure that others on the project were able to quickly access the results of the scanning efforts.

“I wanted to make sure that the subcontractors all had access to the walkthrough and knew how to use the software. So I set them all up with that, and give them a brief rundown of how to navigate and take measurements… I know a few team members have used that and now rely on that information.”

Finally, Gray set up the scan’s origin so that it could exist within the models provided from architects and engineers on the projects.

The results of the scanning and modeling also revealed an unexpected problem that could have severely affected the project if not caught sooner, revealed Martinez.

“After we’d scanned the spaces, we found that the floor levelness was an issue. Scanning enabled us to learn that early, and to allocate part of the budget towards correcting that issue during construction.”

A new tool for fast-paced projects

For the team at Bulley & Andrews, this test demonstrated that cost savings were possible without sacrificing accuracy. In projects with shortened timelines or limited jobsite access, or those that need a quick way to get everyone on board, the NavVis reality capture solution, which combines NavVis VLX hardware and NavVis IVION software, can be a powerful tool to meet those goals.

“It’s a very helpful tool, especially in markets like these where speed s the name of the game - the faster you can get models pulled together the better,” said Martinez.

“If you’ve got a pretty aggressive schedule and a lot of square footage to cover, I would highly recommend [NavVis VLX] over the traditional tripod scan setup.”

Want to learn more about how the NavVis Reality Capture Solution can accelerate your scan-to-BIM timelines?

Chat with a NavVis Expert