Intergraph PPMannounced on May 19 at SPAR 2004 that the next release of SmartPlant Review would provide vendor-neutral point cloud data integration. Here’s an update on the progress of integration with BitWyse’s LASERGen – we had an early peek at the software, which will be shown next week at Intergraph’sAPEX Summitmeeting in Houston. According to Intergraph’s Keith Denton, Point Cloud Integrator will ship before the end of the year; list price is $1650. (We’ll keep you informed about the progress of integration with other laser scanning applications in coming SparViews.)Process and power plants, offshore platforms, bridges, airports, hospitals – all capital projects of any size undergo rigorous design review. Laser scanning promises to be valuable for aligning client expectations with contractor deliverables – except there’s been no ready way to bring point clouds into the visualization software used in design

walkthroughs.

We talked to some EPC firms and owner/operator companies who have also had a first look at this new solution – they give the concept high marks. We regret we can’t provide you their names – we were unable to get the necessary approvals in time.

Design review key to client approval

One EPC executive, who asked not to be identified, reports his company currently uses SmartPlant Review to “let the client see what his plant’s going to look like prior to its being fabricated and erected. That’s key to the approval process.” For greenfield projects, he reports, the process at most PDS users was simply to create a model in PDS, then bring it into

SmartPlant Review for review with the client. Meanwhile, “for revamp work, in the past most companies using a 3D design system sent workers into the field to measure adjacent geometry, then modeled it so the client would have some idea of what was there when we routed the new pipe through the plant.”

Previously SmartPlant Review could only display PDS data, not laser scan data. “LASERGen data works well in the PDS environment. But when we went to get client review and signoff, the client couldn’t see it” because LASERGen did not work with SmartPlant. This is where the

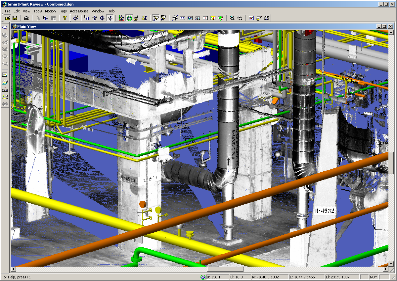

new BitWyse tool comes in. “Now we’ll be able to bring the as-built laser data into Intergraph’s fast review tool. We’ll be able to see all the new design data – electrical, physical, piping – in the context of the as-built environment.”

So why not just use PDS for design review? “PDS is cumbersome to operate as a review tool. SmartPlant Review fixes that. It’s a rendered model, you can navigate it quickly and easily, and it has all the discipline data – you see it all at one time. You can do that in PDS, but it’s incredibly slow.” According to Intergraph’s Denton, the big value of Point Cloud Integrator is that “it allows more non-CAD users access to point cloud data in a fit-for-purpose design review environment.”

Laser scan data in design reviews – why?

Why the need to include laser scan data in design reviews? “Because the client couldn’t see the laser scan data, they didn’t want to pay for it,” our EPC source told us. In fact, this EPC reports, one client “was so adamant about that, we were preparing to make a copy of the PDS

database, load it onto an external hard drive, take it to the client’s site, and use PDS” so the client could review the design in the context of LASERGen data. “So the timing of BitWyse’s tool couldn’t have been better for us.”

Here’s one example of how the new tool can help. “A revamp sometimes involves just routing one line to tie something in – say, an isolation valve in a presumably inaccessible area. We would try to route the pipe to this isolation valve on the existing platform that the client already has in his plant.” But without the point-cloud data, there’s a problem. “When you look at the PDS model in SmartPlant Review without the LASERGen data, you don’t see the platform. You have to say to the customer, ‘Trust me, you have a platform there.’ But they want to see what’s there, and what they’re getting. Of course [design review]can be done in PDS with LASERGen, but the manipulation of the data file is terribly slow.”

The EPC sums up: “In this revamp world, over the last 10 years everyone has gotten on board with 3D design. But nobody spent the time or money for going back to the design database and modeling changes in structure, changes in pipe. LASERGen has fixed that. So getting LASERGen data into a review tool is the next major milestone.”

Accelerating client signoff

Based on firsthand experience, this individual reports the new software lets users “zoom in and out, pan around, clip the LASERGen data, and clip the PDS data. It’s pretty fast. And you can take measurements between PDS data and LASERGen data.” He sums up: “None of the

SmartPlant Review functionality has gone away. What they’ve done is increase the functionality by letting LASERGen data reside in SmartPlant Review and be accessible to all the tools Intergraph has developed for SmartPlant Review.”

Boon for construction management

According to BitWyse president Mark Klusza, this functionality will be a boon for construction management. “Now contractors can see the real plant data together with the design data in a construction-friendly environment – this brings reality to the design review process.”